In the world of packaging, corrugated boxes have become an essential component. From shipping fragile electronics to storing household items, these boxes offer a versatile and reliable solution. But what exactly is a corrugated box, and what makes it different from other forms of cardboard packaging? Let’s explore in detail.

What is a Corrugated Box?

A corrugated box is a type of packaging made from a combination of paper materials. It consists of a fluted corrugated medium sandwiched between two flat linerboards. The fluted layer provides strength and cushioning, making it ideal for protecting and transporting a wide variety of goods. The construction of the corrugated box gives it the ability to withstand stacking, impacts, and rough handling during transit. This unique design allows for the safe delivery of products across different distances and terrains.

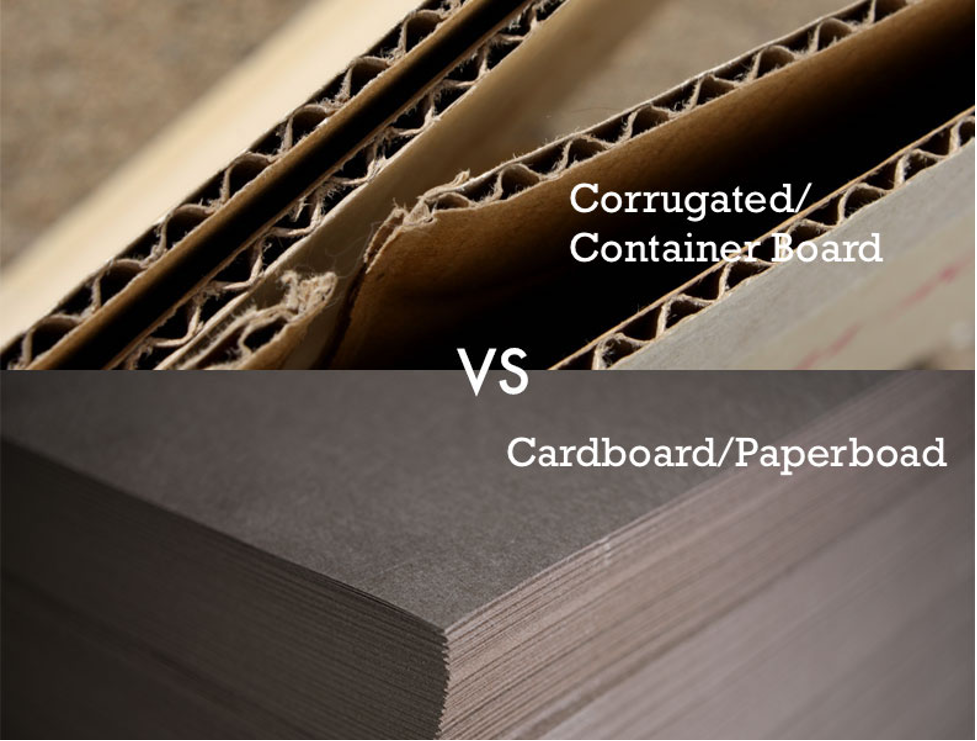

Cardboard vs Corrugated – What’s the Difference?

While both cardboard and corrugated boxes are made from paper, there are significant differences. Cardboard is a general term that often refers to a thicker and more rigid type of paperboard. It is usually used for lighter-duty applications such as cereal boxes or small product packaging. Cardboard is typically a single-layer or double-layer material and lacks the internal fluting structure of corrugated boxes. On the other hand, corrugated boxes have a distinct three-layer or more structure. The fluted layer in corrugated boxes gives them enhanced strength and durability, making them suitable for heavier and more fragile items. Corrugated boxes can handle greater compressive forces and are better equipped to protect contents from shocks and vibrations.

Liners Materials

The linerboards used in corrugated boxes can be made from different materials. One common material is kraft paper. Kraft linerboards are known for their strength and durability. They are made from wood pulp and can vary in thickness and quality. Another option is recycled linerboard, which is an environmentally friendly choice. Recycled linerboards are made from post-consumer waste paper and can offer a sustainable packaging solution. The choice of linerboard material depends on factors such as the intended use of the box, the weight and fragility of the contents, and the desired level of environmental friendliness.

Corrugated Flute Types

Corrugated boxes come in different flute types, each with its own characteristics. The most common flute types include A, B, C, E, and F. Flute A has the largest flute size, providing excellent cushioning and protection. It is often used for fragile items that require a lot of shock absorption. Flute B is a medium-sized flute, offering a balance between cushioning and stacking strength. It is suitable for a wide range of products. Flute C has a smaller flute size and provides higher stacking strength. It is commonly used for heavier items. Flute E and F have even smaller flute sizes, making them ideal for applications where a smooth printing surface or a thinner box profile is required, such as for packaging cosmetics or small electronics. The choice of flute type depends on the specific needs of the product being packaged, including its weight, fragility, and the desired appearance of the box.

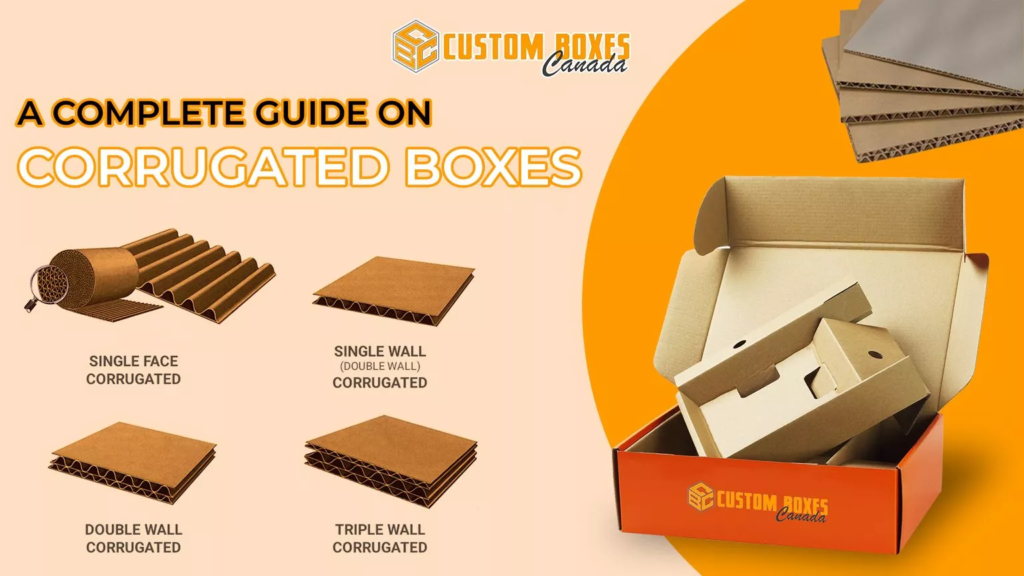

Types of Corrugated

There are several types of corrugated materials available. Single-wall corrugated is the most basic and widely used type. It consists of a single layer of fluted medium between two linerboards and is suitable for many general-purpose packaging needs. Double-wall corrugated has two layers of fluted medium and three linerboards, providing increased strength and durability. It is often used for heavier or more valuable products that require extra protection. Triple-wall corrugated is the most robust option, with three layers of fluted medium and four linerboards. It is used for extremely heavy or oversized items that need maximum protection during shipping and storage.

Corrugated Box Styles

Corrugated boxes come in a variety of styles to meet different packaging requirements. The most common style is the regular slotted container (RSC), which has flaps on the top and bottom that meet in the middle when closed. It is easy to assemble and is widely used for shipping and storage. Another style is the full overlap box, where the flaps on the top and bottom completely overlap each other, providing extra strength and protection. There are also die-cut boxes, which are custom-shaped to fit specific products. These boxes can have unique designs and openings to enhance the presentation and functionality of the packaging. Folding cartons are another option, which are made from thinner corrugated material and are often used for retail packaging where a more refined appearance is desired.

Quality Control Tests

To ensure the quality and performance of corrugated boxes, several quality control tests are conducted. One important test is the burst strength test, which measures the ability of the box to withstand internal pressure. This is crucial for preventing the box from bursting open during handling or stacking. The edge crush test is another key test. It determines the compressive strength of the box along its edges, which is important for maintaining the box’s shape and integrity when stacked. The box compression test measures the maximum load a box can withstand before collapsing. This test helps in determining the appropriate stacking height and shipping conditions for the boxes. Additionally, there are tests for moisture resistance, as excessive moisture can weaken the corrugated material and affect the box’s performance.

Box Maker’s Certificate

A box maker’s certificate is a document provided by the manufacturer that attests to the quality and specifications of the corrugated box. It includes information such as the box dimensions, the type of corrugated material used (including flute type and linerboard material), the bursting strength, and the edge crush strength. The certificate gives assurance to the customer that the box meets certain quality standards and is suitable for its intended purpose. It is especially important for industries where product safety and integrity during shipping are critical, such as the electronics, pharmaceuticals, and food industries.

Benefits of Corrugated Packaging

Corrugated packaging offers numerous benefits. Firstly, it provides excellent protection for the contents. The fluted layer and sturdy linerboards can absorb shocks, vibrations, and impacts, reducing the risk of damage to the products. Secondly, corrugated boxes are highly customizable. They can be made in different sizes, shapes, and with various printing options to meet the specific branding and marketing needs of a business. Thirdly, they are cost-effective. The materials used in corrugated boxes are relatively inexpensive, and the manufacturing process is efficient, making them an affordable packaging solution, especially for large-scale production. Fourthly, corrugated packaging is environmentally friendly. Most corrugated boxes are made from recyclable materials, and the recycling process is well-established. This makes them a sustainable choice for businesses looking to reduce their environmental footprint.

What About the Disadvantages of Corrugated Boxes?

While corrugated boxes have many advantages, they also have some limitations. One disadvantage is that they are relatively bulky compared to some other packaging materials. This can result in higher shipping costs, especially for products where volume is a significant factor. Another issue is that corrugated boxes may not be suitable for extremely humid or wet environments. Although they can have some level of moisture resistance, prolonged exposure to moisture can cause the box to weaken and lose its structural integrity. Additionally, the appearance of corrugated boxes may not be as refined as some other packaging options, such as plastic or metal containers. This may make them less suitable for high-end or luxury products where aesthetics are a top priority.

Create Your Custom Corrugated Boxes Today!

Pangkai Packaging empowers you to bring your unique vision to life with custom corrugated boxes. Offering a diverse range of high-quality liner materials, an array of flute types for optimal protection and presentation, various box styles to suit any need, and stringent quality control measures with a provided box maker’s certificate. Their service allows you to enhance product protection, showcase your brand through custom printing, and meet all your shipping and storage requirements, making it effortless for businesses of all sizes to obtain the perfect custom corrugated packaging solution today.