In the dynamic world of packaging, Sleeve Boxes have emerged as a popular choice across a diverse range of industries. Selecting the appropriate material for Sleeve Boxes is a crucial decision that can significantly impact a product’s success in the market. This in-depth guide will walk you through the essential considerations, materials available, and strategies to make the best choice for your unique packaging needs.

The Significance of Sleeve Boxes in Packaging

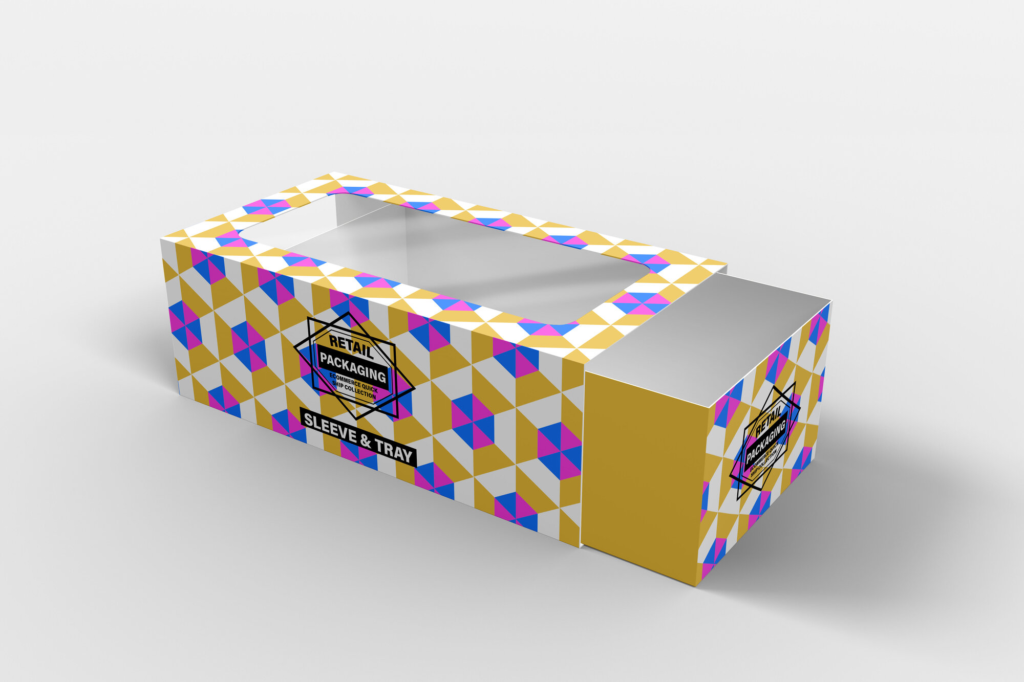

Sleeve Boxes, with their simple yet elegant design, offer a versatile packaging solution. They consist of an outer sleeve that slides over a product or an inner tray, providing an additional layer of protection and an aesthetic appeal. In the retail space, they stand out on crowded shelves, beckoning customers with their clean lines and often customizable exteriors. For e-commerce businesses, they ensure that products arrive in pristine condition, safeguarding against the bumps and bruises of shipping. Moreover, Sleeve Boxes play an instrumental role in shaping a brand’s image. A well-designed, high-quality box can convey luxury, sustainability, or innovation, depending on the material and finish chosen, leaving a lasting impression on consumers.

Understanding Different Materials for Sleeve Boxes

Cardboard

Cardboard is a staple in the packaging industry and a common choice for Sleeve Boxes due to its affordability and ease of customization. It offers a decent level of structural integrity, making it suitable for lightweight products such as paperback books, small stationery items, or novelty gifts. One of its significant advantages is the ability to print vivid graphics and text, allowing brands to showcase their logos, product information, and promotional messages with clarity. However, cardboard is not without its drawbacks. It is vulnerable to moisture damage, which can cause warping and weakening of the box structure. In humid environments or during transit in less than ideal conditions, this can pose a risk to the contents. Additionally, it may not withstand the weight of heavier items, and over time, with repeated handling, it can show signs of wear and tear if not of a high-enough quality grade.

Kraft Paper

Kraft paper has witnessed a surge in popularity, primarily driven by the growing consumer demand for sustainable packaging options. Made from wood pulp processed through the kraft process, it has a natural, rustic look that lends itself well to brands with an organic or earthy aesthetic, like artisanal food producers, handmade crafts businesses, or eco-friendly personal care brands. Its strength lies in its tear resistance, which ensures that the Sleeve Boxes can endure normal handling without easily ripping. On the flip side, the rough texture of kraft paper can make high-quality, detailed printing a bit more challenging compared to smoother materials. The resulting print may not have the same level of sharpness and vibrancy, which could be a consideration for brands that rely heavily on visual branding elements.

Corrugated Cardboard

When it comes to protecting fragile items during shipping, corrugated cardboard reigns supreme. The unique fluted layer sandwiched between two flat liners provides excellent shock absorption capabilities, making it the go-to material for packaging electronics, glassware, ceramics, and other breakable products. It is highly durable and can withstand stacking, both in warehouses and on retail shelves, without collapsing under pressure. Despite its robustness, corrugated cardboard is bulkier than some other options, which means it requires more storage space and can add to shipping costs due to its increased weight and volume. Its appearance is also more utilitarian, which might not align with the image of luxury or high-fashion products seeking a sleeker packaging look.

Rigid Paperboard

For luxury brands looking to make a statement, rigid paperboard is the material of choice. It exudes a premium feel, with a smooth surface that allows for high-quality finishes such as embossing, foil stamping, and spot UV coating. These embellishments can transform a simple Sleeve Box into a work of art, elevating the unboxing experience for customers. Brands in the high-end cosmetics, fine jewelry, and luxury watch sectors often opt for rigid paperboard to convey sophistication and exclusivity. However, this luxury comes at a price. Rigid paperboard is considerably more expensive than its more basic counterparts, and its rigidity can limit the complexity of shapes and designs achievable during manufacturing, requiring more precision and expertise in production.

Plastic

Plastic Sleeve Boxes offer unique advantages, particularly in terms of moisture and waterproofing. Clear plastic sleeves, for example, allow consumers to see the product inside without fully removing the packaging, creating an immediate visual connection that can enhance product appeal. They are highly resistant to scratches and impacts, ensuring that the contents remain protected during handling and display. In industries like bath and body products, where water exposure is a concern, or for toys and novelty items that need to withstand rough play, plastic sleeves provide reliable protection. Nevertheless, the environmental implications of plastic are a significant drawback. Many plastics are not easily recyclable, and their production processes can have a negative impact on the environment if not sourced and managed responsibly. Additionally, lower-quality plastics can have a plasticky, unappealing feel that might detract from the overall product perception.

Factors Influencing Material Selection

Product Characteristics

The nature of the product being packaged is the starting point for choosing the right Sleeve Box material. Weight plays a crucial role; heavier items demand materials with greater strength and load-bearing capacity, such as corrugated cardboard. Fragile products, like glass vases or delicate electronics components, require materials that can absorb shocks and vibrations during transit, again pointing towards corrugated or thick rigid paperboard with added cushioning features. The shape and size of the product also factor in; irregularly shaped objects may need custom-cut or flexible materials to ensure a snug fit within the sleeve, preventing movement that could lead to damage.

Brand Image and Target Audience

Your brand’s identity and the preferences of your target audience should guide your material selection. Luxury brands aiming to create a sense of opulence and exclusivity will gravitate towards rigid paperboard with lavish finishes. Their customers expect a tactile and visual experience that screams quality and refinement from the moment they lay eyes on the packaging. In contrast, eco-conscious brands will find kraft paper or recycled cardboard a natural fit, as it signals their commitment to sustainability and resonates with environmentally aware consumers. For mass-market retailers dealing with everyday consumer goods, cost-effective materials like standard cardboards strike the right balance between durability and price, appealing to budget-conscious shoppers.

Storage and Transportation Conditions

The journey your product takes from the manufacturing facility to the end consumer’s hands impacts material choice. If products will be stored for extended periods, materials resistant to environmental factors like humidity, temperature fluctuations, and pests are essential. Cardboard might not be the best option for long-term storage in damp warehouses, while plastic or coated paperboards could fare better. Shipping methods also matter; for local deliveries, a lighter, more cost-effective material might suffice, but for international shipments that involve multiple handling points and longer transit times, the robustness of corrugated cardboard or thick rigid paperboard becomes crucial to prevent damage.

Sustainability Considerations

In today’s environmentally conscious marketplace, sustainability cannot be overlooked. The recyclability of Sleeve Box materials is a key aspect. Kraft paper and many types of cardboard are highly recyclable, fitting into existing waste management systems and reducing the overall environmental impact. Brands should look for suppliers that adhere to sustainable forestry practices, ensuring that the raw materials are sourced responsibly. For plastics, opting for recyclable or biodegradable varieties can mitigate the negative environmental footprint. Additionally, considering the energy consumption and emissions associated with the production and transportation of materials helps in making a more holistic, sustainable choice.

Cost Analysis

Upfront Material Costs

There is a wide cost spectrum among Sleeve Box materials. Cardboard and kraft paper are generally more budget-friendly options, making them attractive for startups and businesses with tight cost constraints. Rigid paperboard and specialty plastics, on the other hand, come with a heftier price tag due to their quality, manufacturing processes, and finishes. Understanding the per-unit cost of materials is essential in budgeting for packaging expenses, especially when dealing with large production runs.

Long-Term Cost Implications

While upfront costs are important, the long-term financial impact must also be considered. Durable materials like corrugated cardboard and rigid paperboard may have a higher initial investment but can save costs in the long run by reducing the need for frequent replacements due to damage. They also minimize the risk of shipping damage claims, which can be costly for businesses. Additionally, materials that are easier to store and handle can lead to operational efficiencies, further offsetting the initial cost difference.

Case Studies

Successful Implementations of Different Materials

Take the example of a local artisanal chocolate brand that switched from plastic packaging to kraft paper Sleeve Boxes. The rustic charm of the kraft paper aligned perfectly with their handcrafted, natural product image. The result was increased customer engagement, with consumers drawn to the sustainable and aesthetically pleasing packaging, leading to a significant boost in sales. In the electronics sector, a leading smartphone brand uses corrugated cardboard Sleeve Boxes for shipping, ensuring that their delicate devices reach customers intact, despite the rigors of global logistics. The sturdy boxes have become synonymous with the brand’s reliability, enhancing customer trust.

Lessons Learned from Poor Material Choices

A beauty startup once chose a thin, low-quality cardboard for their luxury makeup Sleeve Boxes, aiming to cut costs. However, the boxes arrived damaged at customers’ doors, leading to negative reviews and a damaged brand reputation. They had to recall the products and invest in new, rigid paperboard boxes, incurring significant financial losses. Another company used non-recyclable plastic sleeves for their eco-friendly household products, facing a public backlash for the contradiction between their product values and packaging choices, highlighting the importance of aligning material selection with brand messaging.

Conclusion

Choosing the right material for Sleeve Boxes is a multifaceted decision that intertwines product protection, brand identity, sustainability, and cost considerations. By carefully evaluating the product’s characteristics, understanding your brand’s target audience, factoring in storage and transportation needs, and weighing the environmental and financial implications, you can make an informed choice that maximizes the value of your packaging. Remember to test samples, consult with packaging experts, and stay attuned to industry trends to ensure that your Sleeve Boxes not only safeguard your products but also tell a story that resonates with consumers in an increasingly competitive marketplace.